ADDITIVE

Pursuing our aziendal policy of attention to the Client, but also driven by our Love for Technological Innovation, we acquired a new productive technology, Additive Manufacturing.

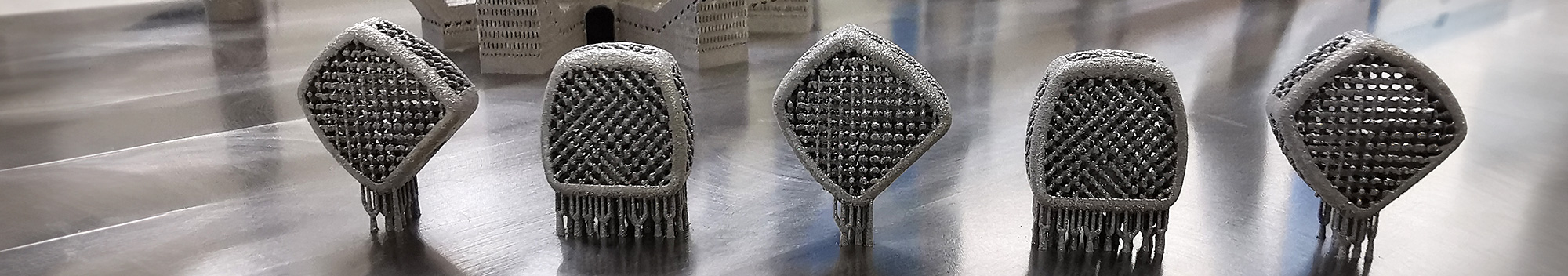

The approach path to Additive Manufacturing (AM) lasted almost a year, that we used to perform machine installation, laboratory proofs, chemical and metallografical analysis, tribological proofs, staff training and production of pre- series.

Our attention to Client and Quality of products drove us to offer this new technology only at the end of this journey, to be able to offer a complete AM service, complemented with machine and process validation, to guarantee the overall safety of the results.

At present we are able to project and produce Client’s products, ensuring also the conformity to the main applicable quality standards to this kind of operations.

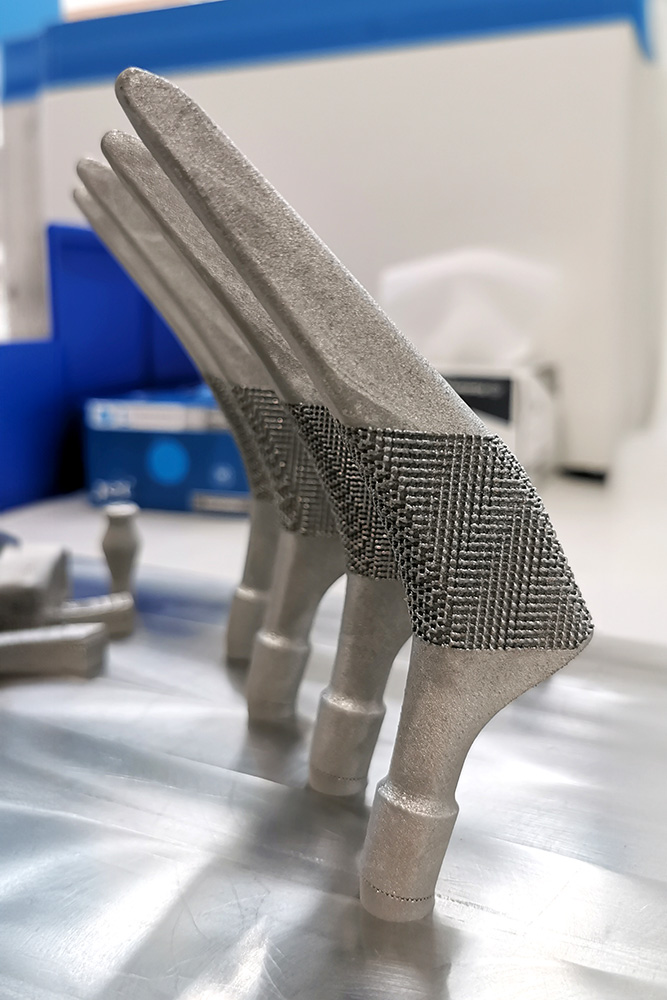

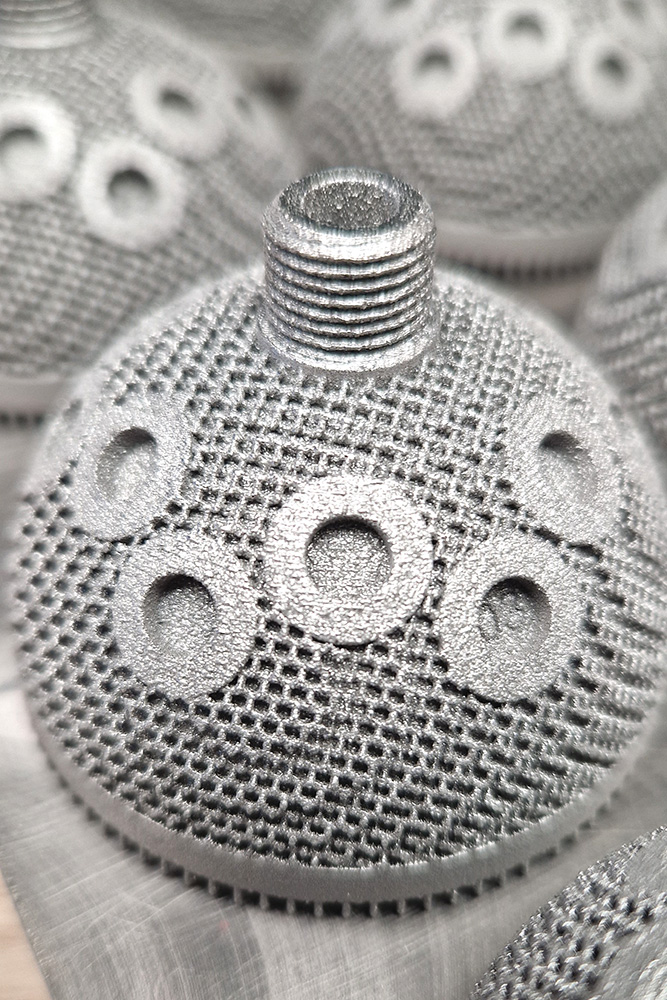

We use the innovative technology of Additive Manufacturing denominated “ Selective Laser Melting” (SLM), performing prints in implantable titanium alloy.

Our experience in AM is focused on traumatology, dental and spinal field, we are able to carry on subsequently CNC operations, surface finishing and validated cleanings on AM parts, so we are able to deliver to our Client a finished Medical Device “key-in -hand”.

To better keep under control the AM activities we acquired the necessary technology to perform and inspect metallographics specimen( research of Alpha Case, interruption in structure) quickly, directly in our internal Chemical Lab.